THE CLOUDS REST WALL (2021)

구름이 머무는 담장

2023 Red Dot Awards 2023 『Design Concept | Concept | Public Space』 Winner

2021 MCST-Seoul Public Art Project 『25 Episodes of Seoul;』 Winner

2021 KOREA DESIGN AWARD | Finalist

서울시-문체부 공공미술 프로젝트 『서울, 25부작;』 선정작

2021 대한민국공공디자인대상 최종후보

Public Art for An Abandoned Public Wall

Co-Host | the Seoul Metropolitan Government and MCST

Administration | Urban Design Division, Jongno-Gu

Location | Jongno-Gu, Seoul, South Korea

Completion | 2021

Structural Engineer | Eun Structural Engineering

Material | Fluororesin Coating on Extruded Aluminum Module, Galvanized Steel Frame, Stainless Steel Accessories

Dimensions | 35m(W) X 2m(H)

주최 | 서울특별시, 문화체육관광부

주관 | 종로구 도시디자인과

재료 | 압출 알루미늄 모듈 위 불소수지 도장, 아연도금 스틸 프레임, 스테인레스 스틸 부속품

규격|가로 35m X 세로 2m

제작년도| 2021년

사진 | 권보준 작가 ︎ | www.bojune.com

Related

TIDAL WALL

봄 (SEEING, SPRING)

MORNING GLORY CLOUD

How can nature, memory and technology be integrated within public art?

The Clouds Rest Wall: Integrating Nature, Memory, and Technology In Public Art

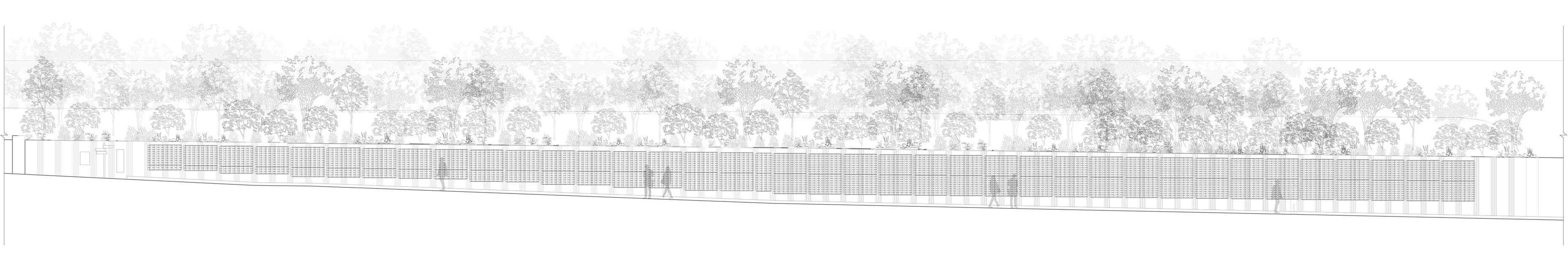

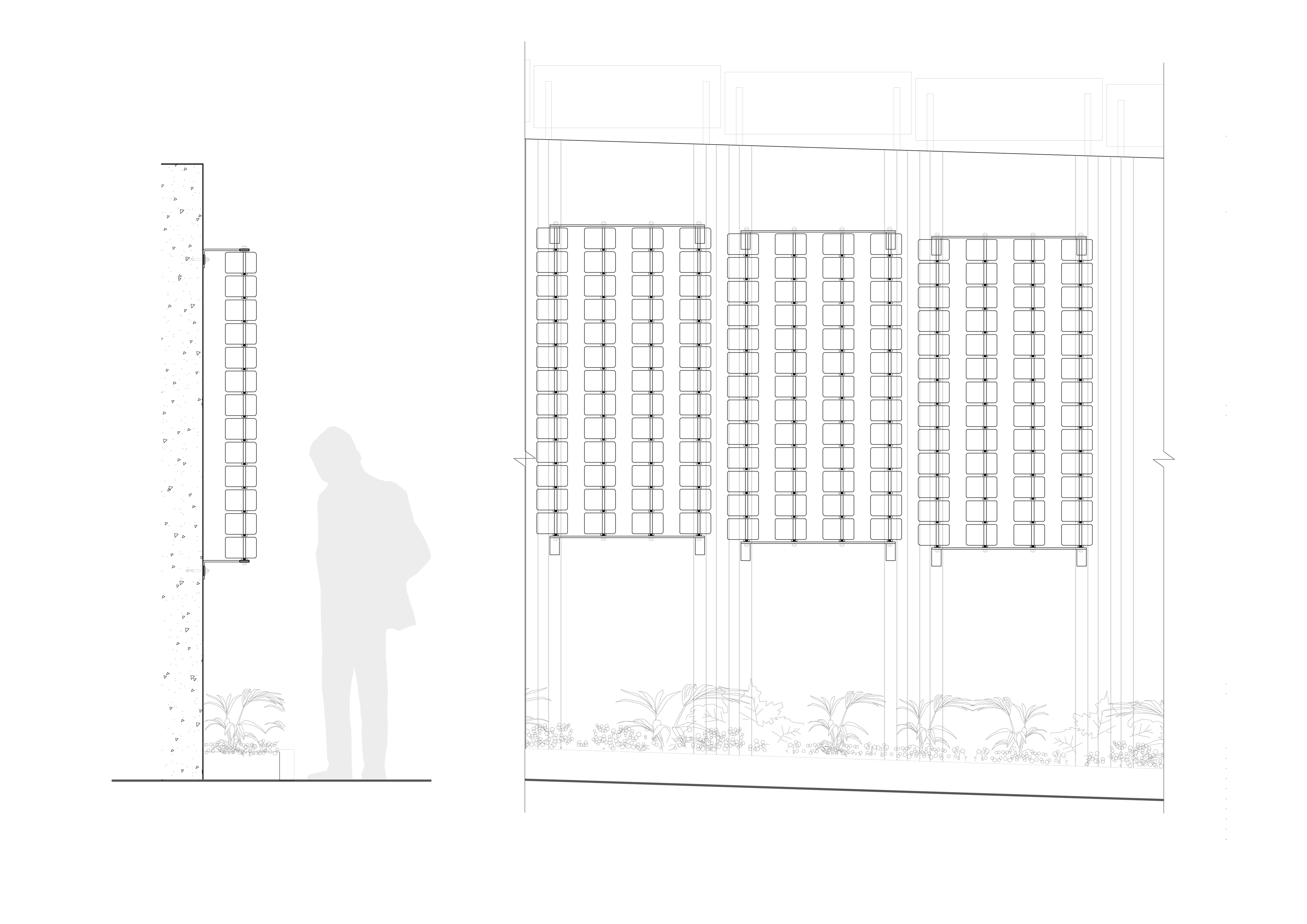

The Clouds Rest Wall revitalizes an aging wall of a high school in Jongno-gu, Seoul, transforming it into a vibrant, community-centered skyscape inspired by the clouds resting over the nearby Bukhansan Mountain. Conceived with the question, “How can nature, memory, and technology be integrated within public art?” this project captures both the ephemeral beauty of the sky and the collective memories of the local community through approximately 4,500 aluminum units, called Cloud Seeds. The 150-meter-long wall has been peeled off after being painted a long time ago; the lower flower bed is also abandoned and damaged.

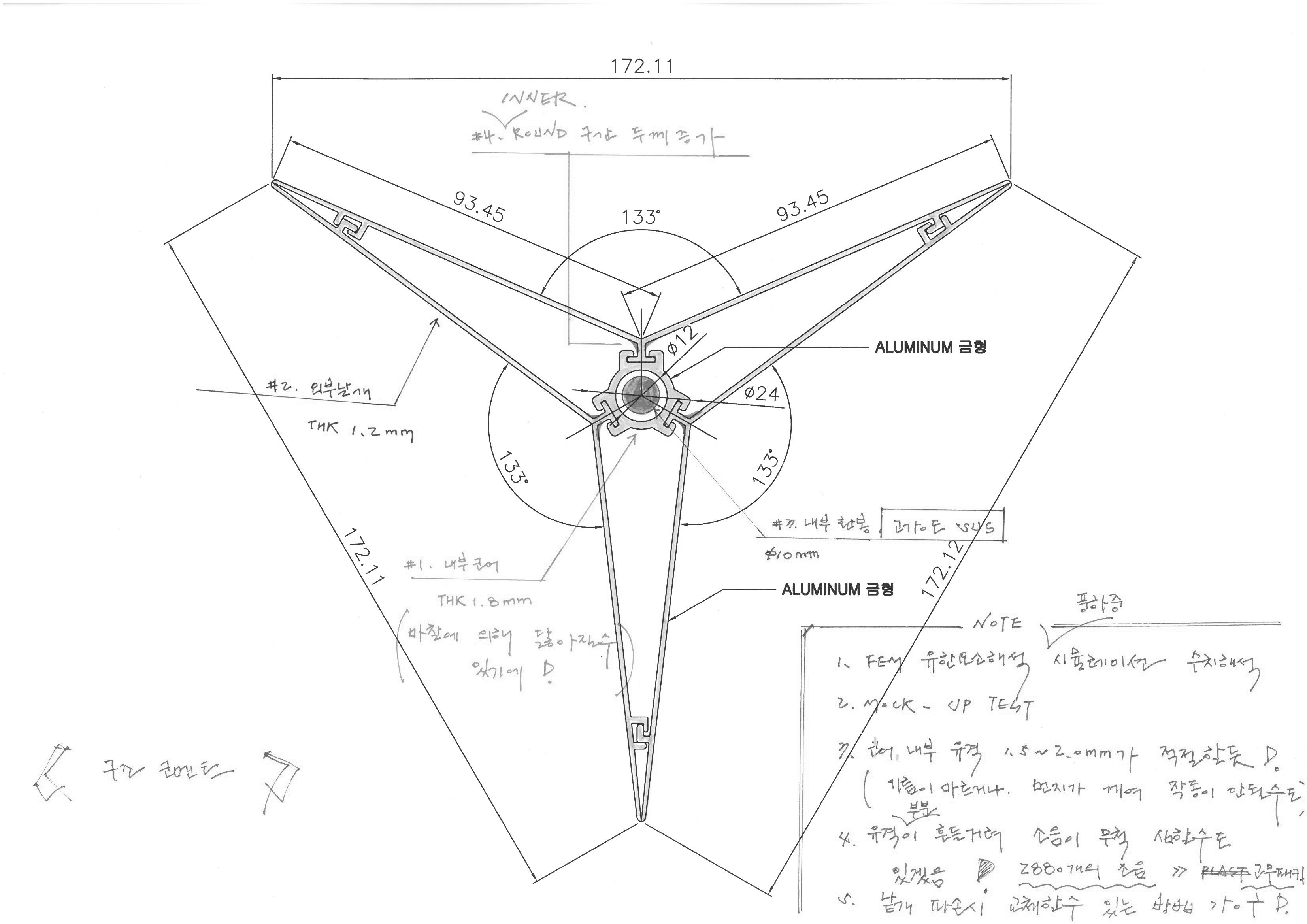

DESIGN

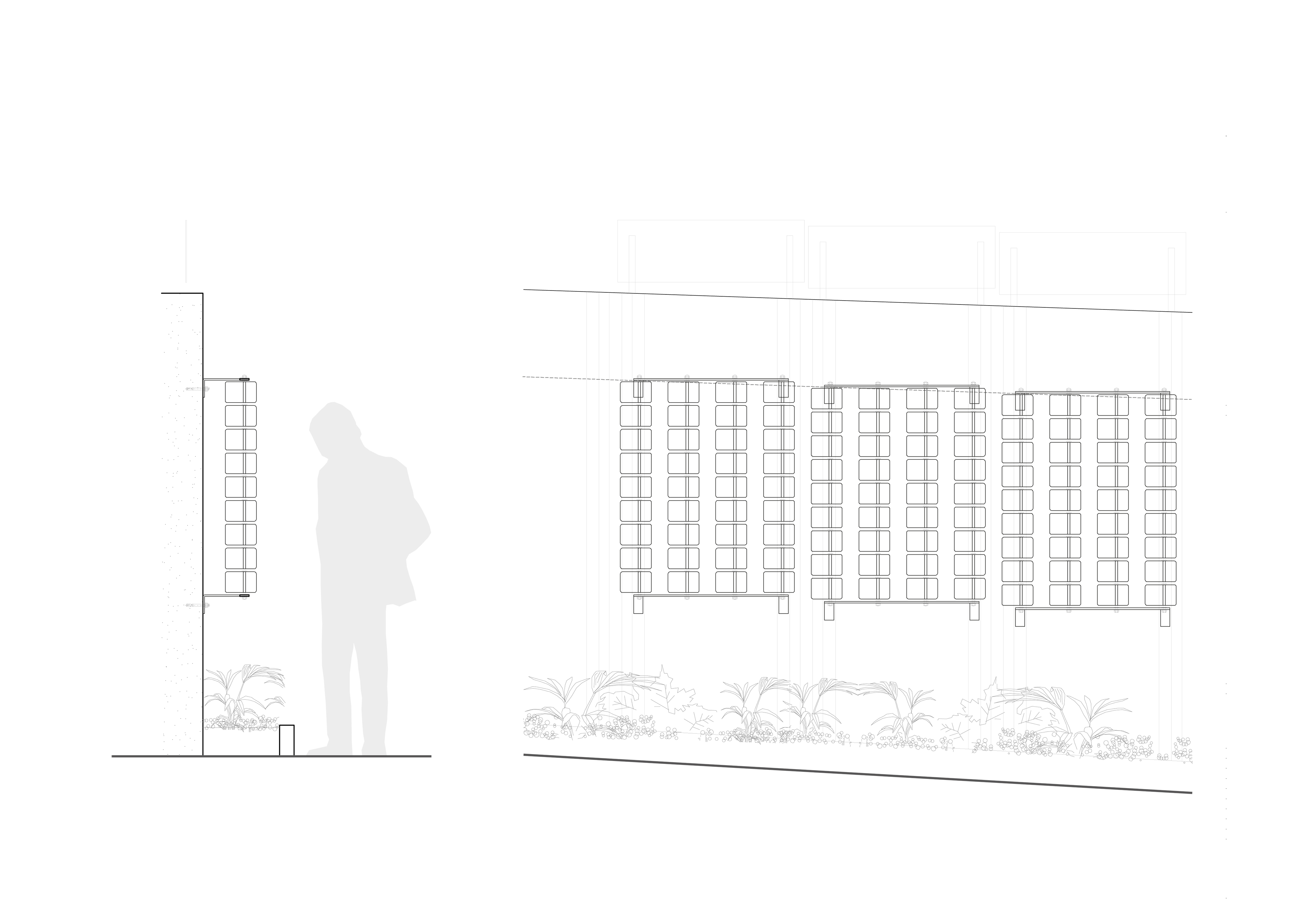

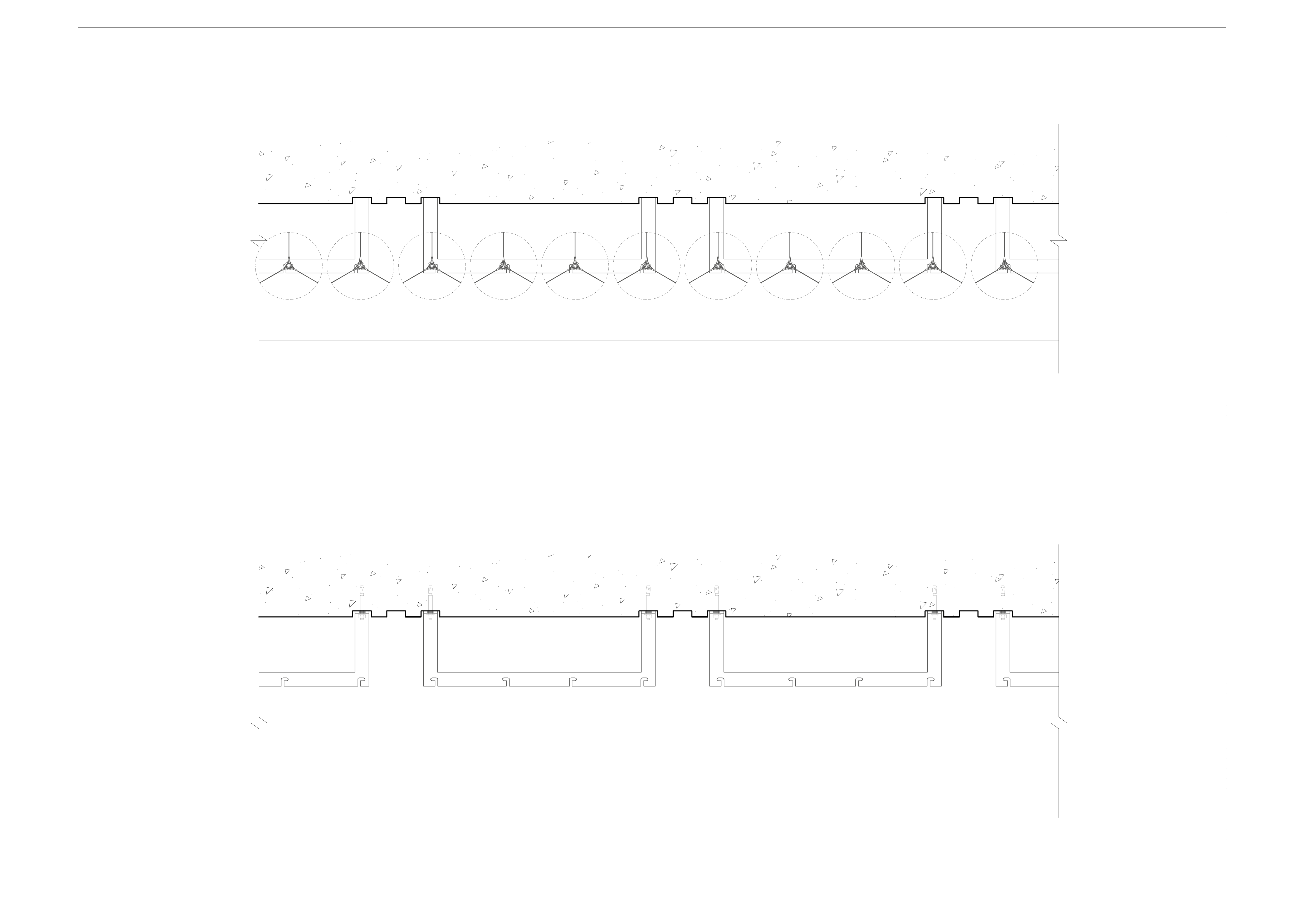

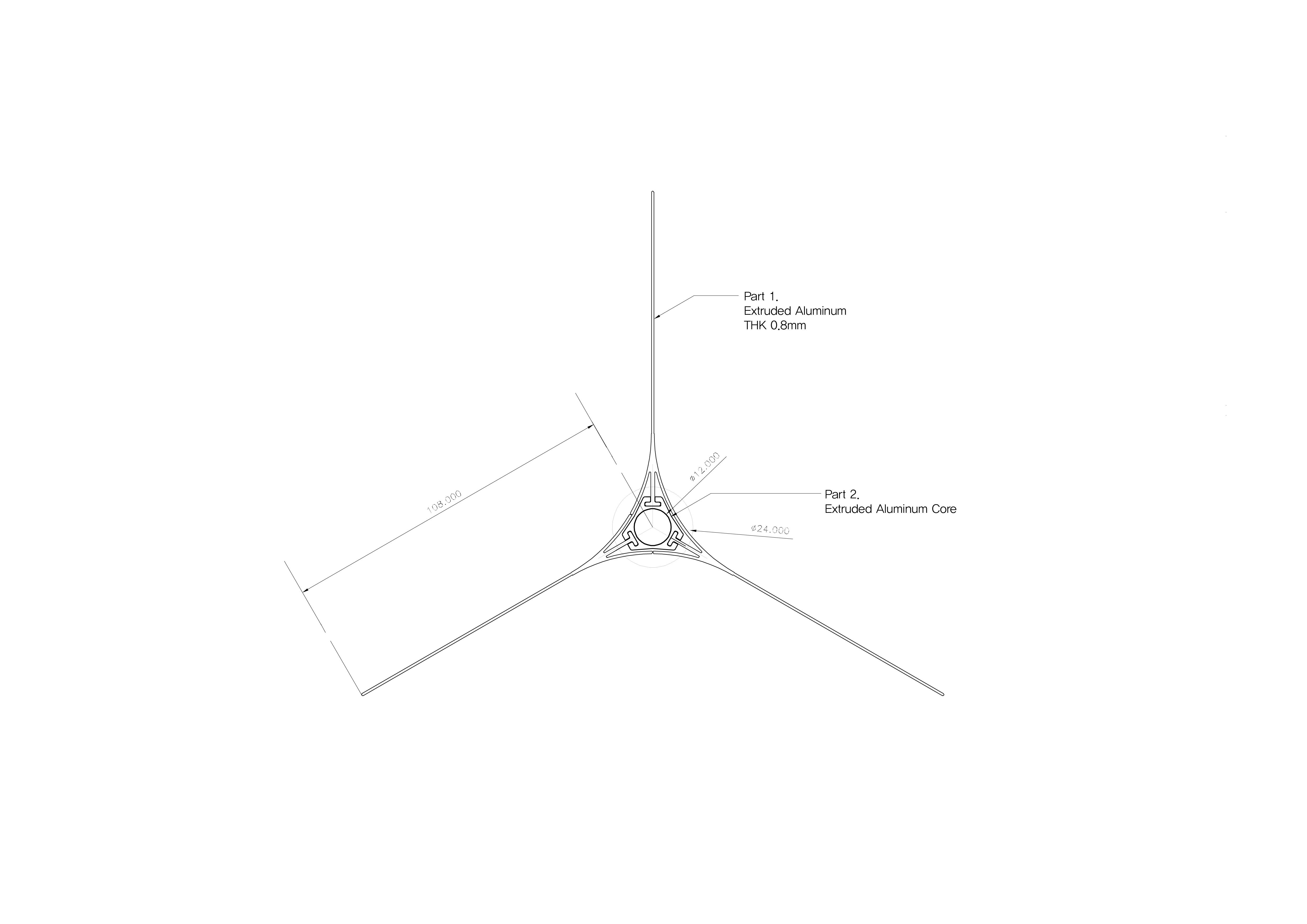

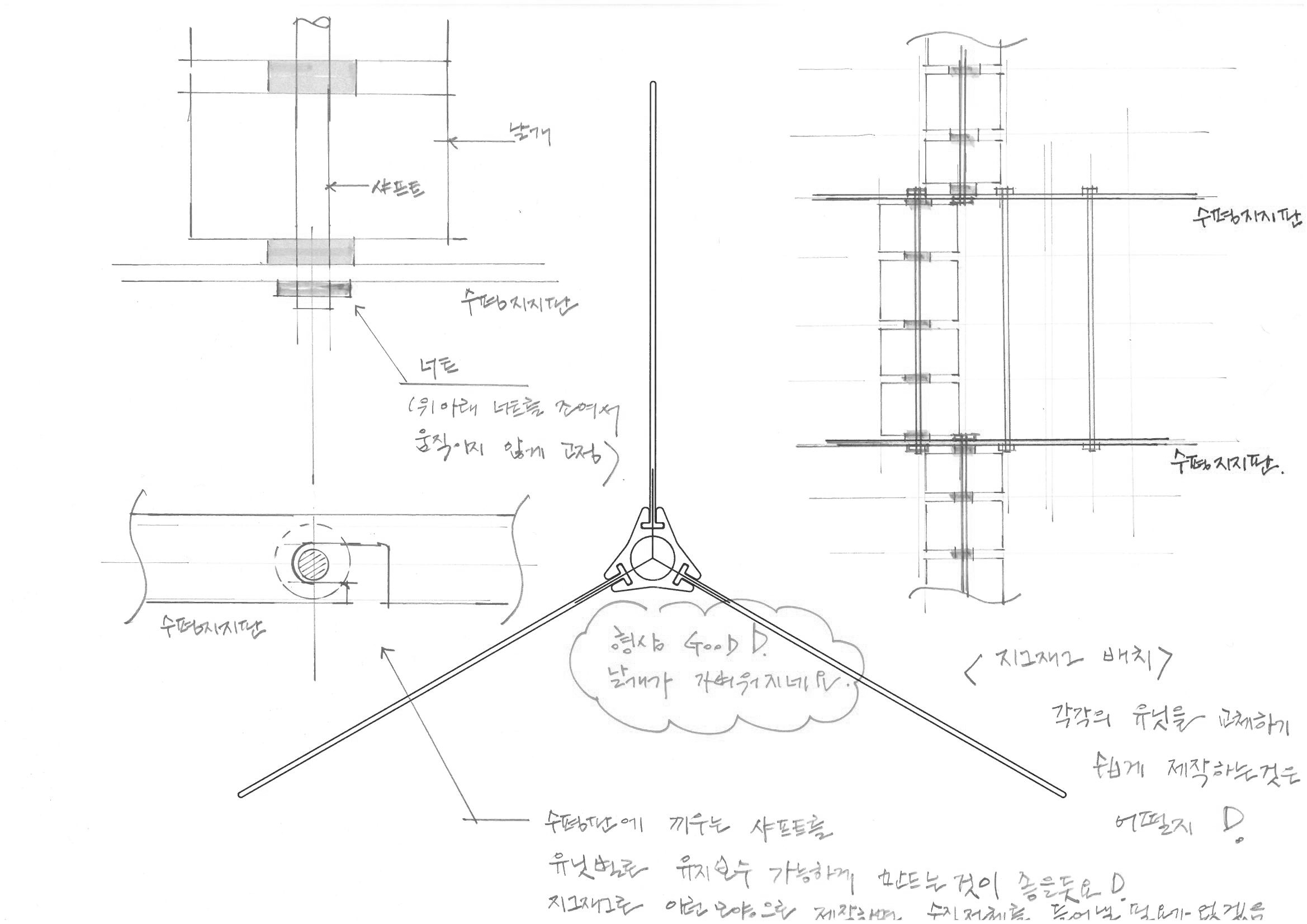

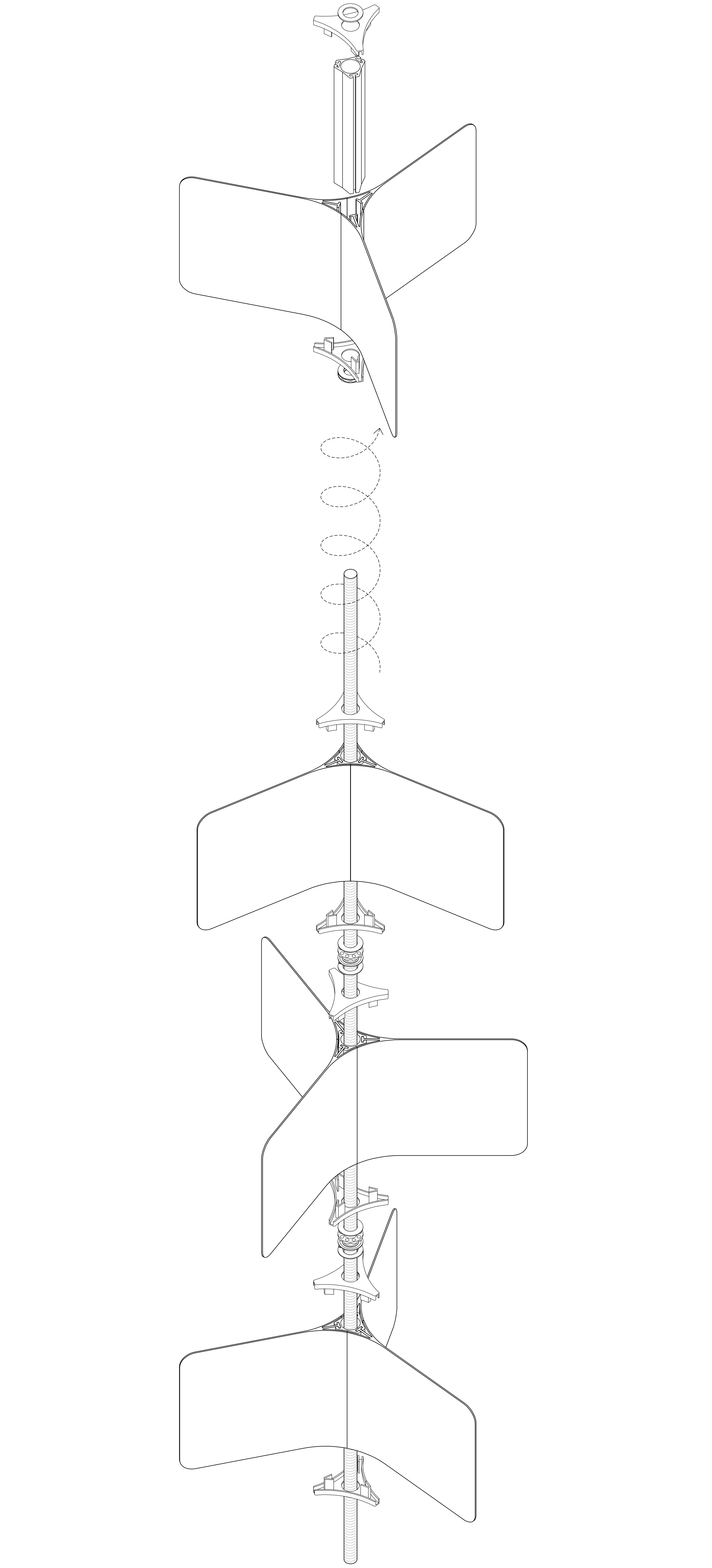

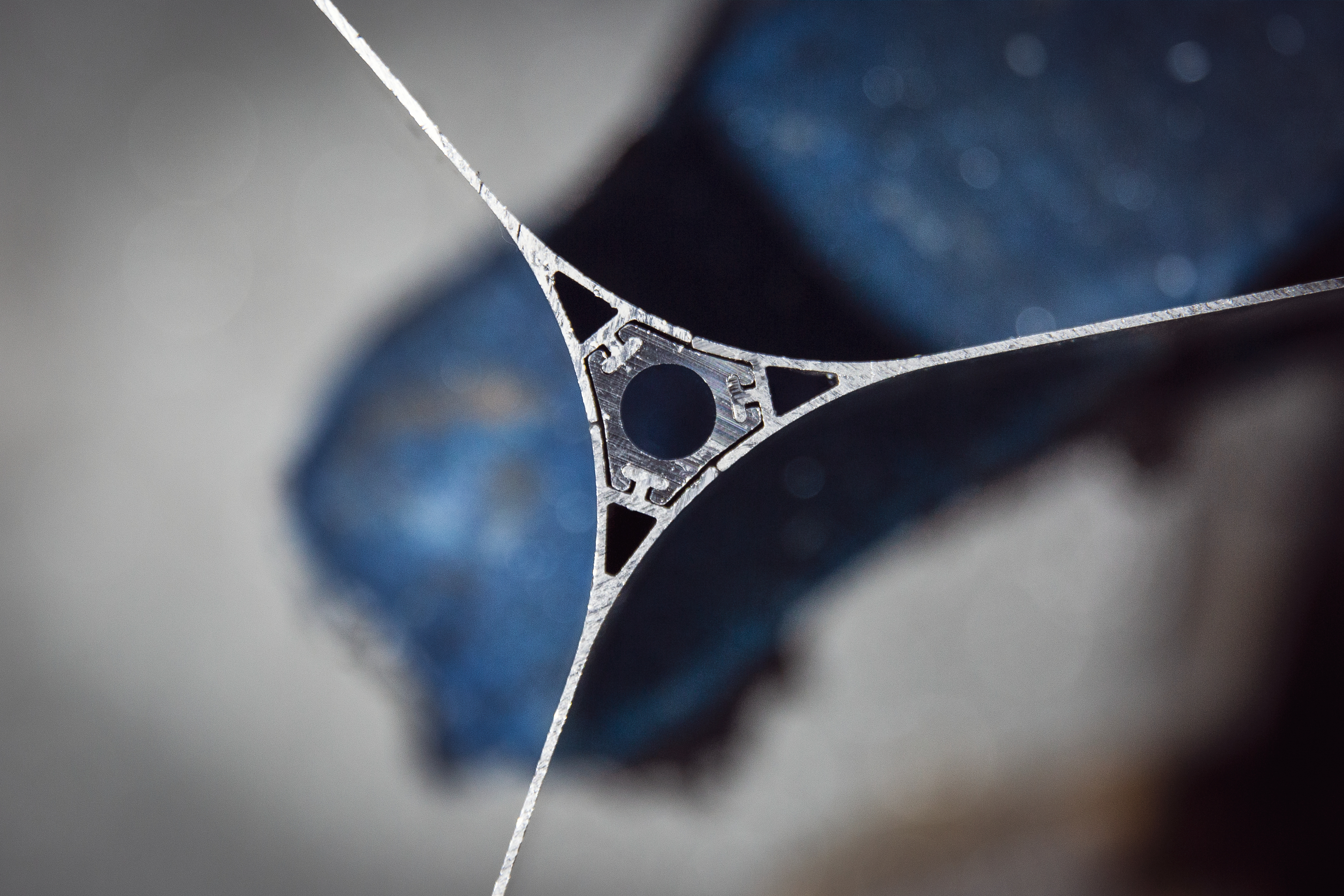

The CLOUD SEEDS, which have a cross-sectional shape like a pinwheel, constantly rotate at various speeds and draw various images of the sky on the wall. at every moment. The CLOUD SEEDS create hundreds or thousands of combinations of sky and clouds by the wind or by the hands of people who pass through this place. The CLOUD SEEDS are made of aluminum for lightweight and durability. The cross-sectional shape governs the structural loads, public safety, and easiness of operation. In collaboration with structural engineers, vertical and wind load, frictional force, and aerodynamics were reviewed; finally, a frame with the minimum structural and visual burden on the existing wall was devised. The steel frame for fixing modules is installed in line with the joint of the wall. While threading CLOUDS SEEDS, steel rods are connected to the horizontal bar and are joined together to the L-shaped angle, which is then fixed to the retaining wall to support the total weight of the assembly.

The CLOUD SEEDS, which have a cross-sectional shape like a pinwheel, constantly rotate at various speeds and draw various images of the sky on the wall. at every moment. The CLOUD SEEDS create hundreds or thousands of combinations of sky and clouds by the wind or by the hands of people who pass through this place. The CLOUD SEEDS are made of aluminum for lightweight and durability. The cross-sectional shape governs the structural loads, public safety, and easiness of operation. In collaboration with structural engineers, vertical and wind load, frictional force, and aerodynamics were reviewed; finally, a frame with the minimum structural and visual burden on the existing wall was devised. The steel frame for fixing modules is installed in line with the joint of the wall. While threading CLOUDS SEEDS, steel rods are connected to the horizontal bar and are joined together to the L-shaped angle, which is then fixed to the retaining wall to support the total weight of the assembly.

FABRICATION

Conducting 1:1 mock-up tests several times in the fabrication lab with a 3D printer and a CNC machine not only allowed us to reduce manufacturing errors but also allowed for prompt pre-assembly in the factory. Mass production and painting in the neighboring factories also accelerated the fabrication process. Each module is finished with PVDF coating to realize various colors and increase heat, cold, and abrasion resistance.

Conducting 1:1 mock-up tests several times in the fabrication lab with a 3D printer and a CNC machine not only allowed us to reduce manufacturing errors but also allowed for prompt pre-assembly in the factory. Mass production and painting in the neighboring factories also accelerated the fabrication process. Each module is finished with PVDF coating to realize various colors and increase heat, cold, and abrasion resistance.

INSTALL & PUBLIC PARTICIPATION

THE CLOUDS REST WALL is completed with photos of the sky collected with the participation of citizens, it allows those who took the photos to stay for a while and touch the Cloud Seeds. The scenery of the sky created by various colors of Cloud Seeds becomes another inspiration for those who come and go to this place every day.

CLOUD SEEDS have different colors on all three sides; the colors are extracted from the photos of skies taken by citizens and converted into 8 PANTONE colors. On top of that, short messages or corresponding information about the colors were inscribed.

THE CLOUDS REST WALL is completed with photos of the sky collected with the participation of citizens, it allows those who took the photos to stay for a while and touch the Cloud Seeds. The scenery of the sky created by various colors of Cloud Seeds becomes another inspiration for those who come and go to this place every day.

CLOUD SEEDS have different colors on all three sides; the colors are extracted from the photos of skies taken by citizens and converted into 8 PANTONE colors. On top of that, short messages or corresponding information about the colors were inscribed.

ⓒ임윤식, 윤대원

ⓒ서울, 25부작; 운영단