THE BEAUTY OF SCIENCE

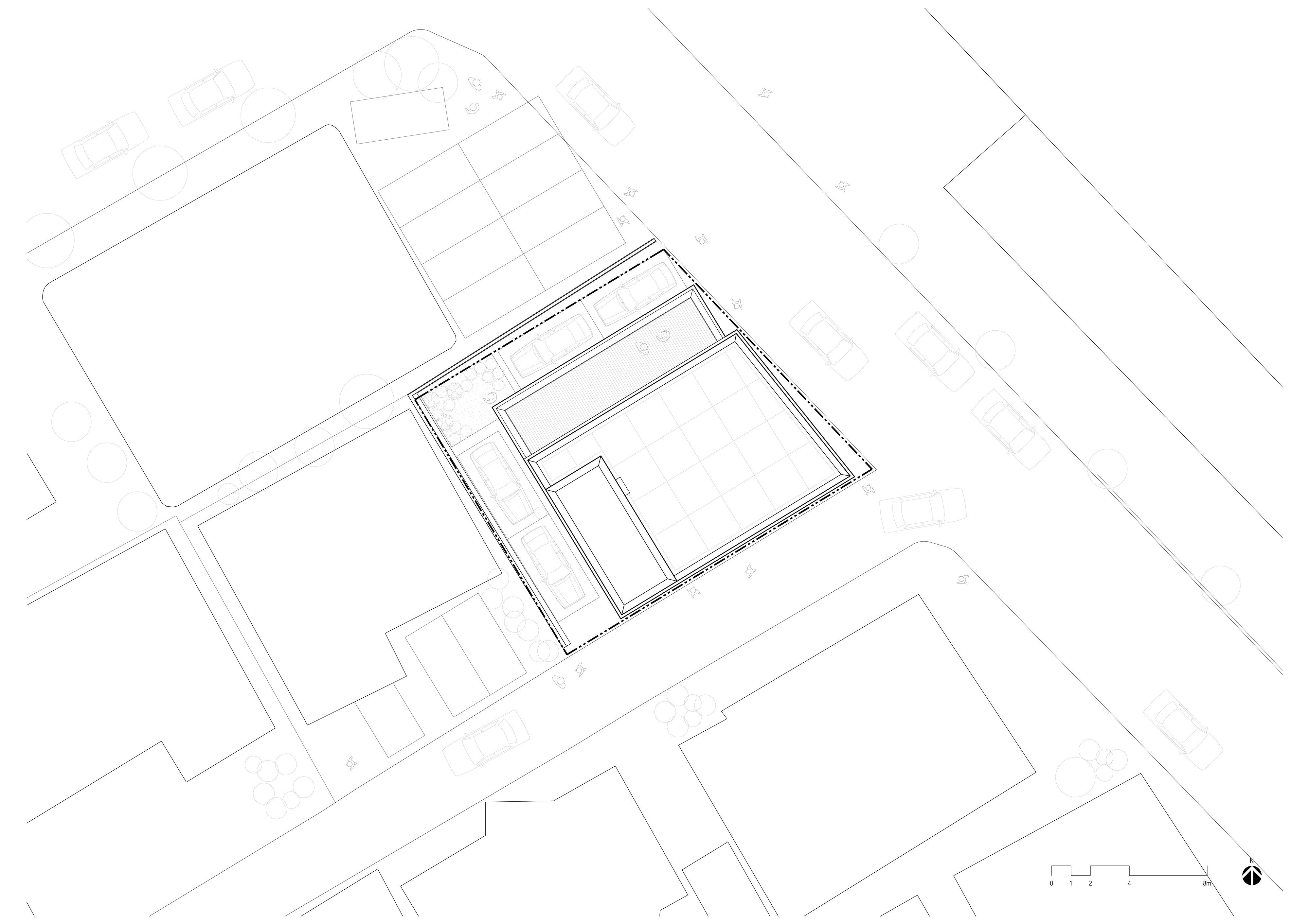

New Headquarter for S CompanyLocation | Mapo-gu, Seoul, South Korea

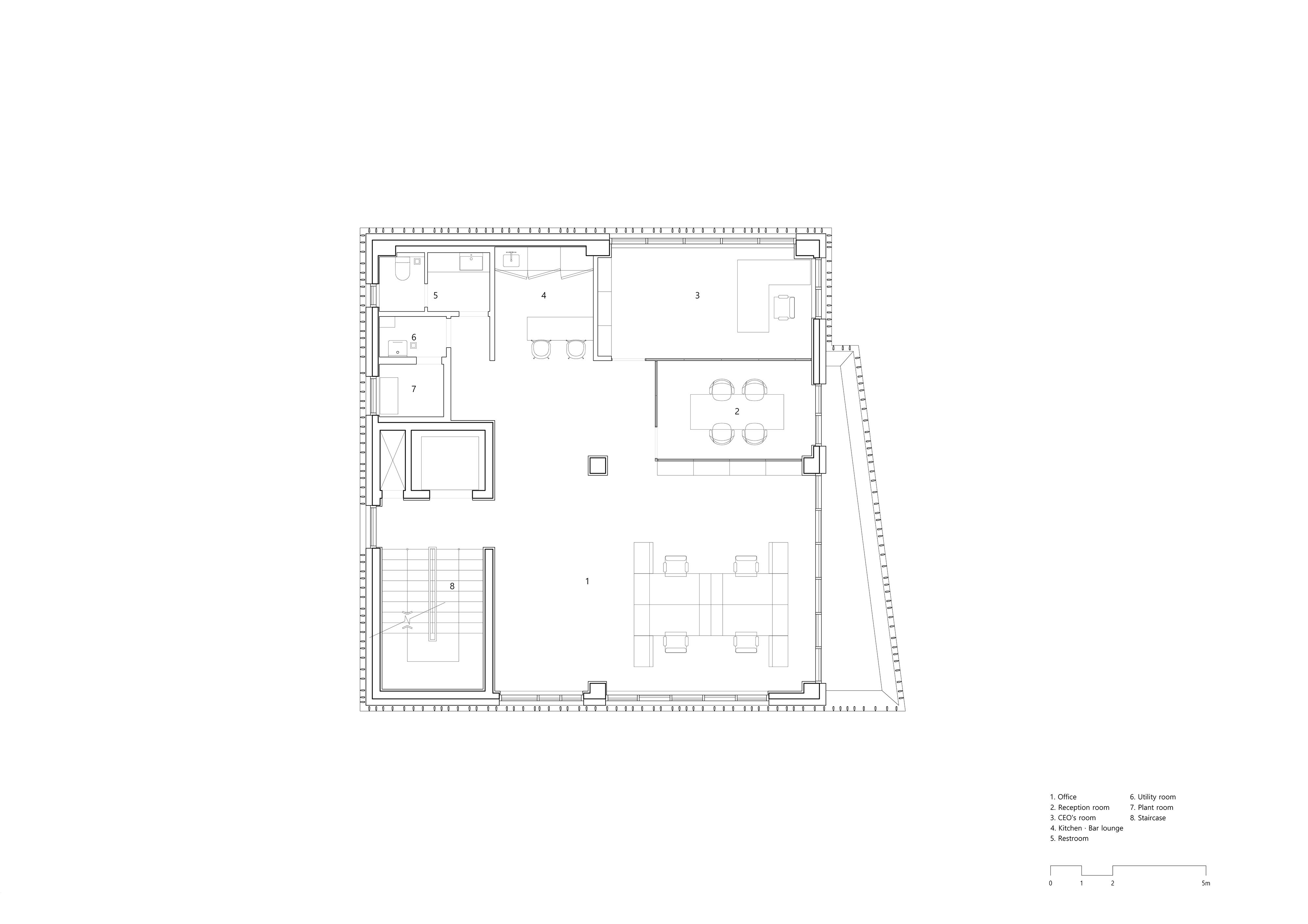

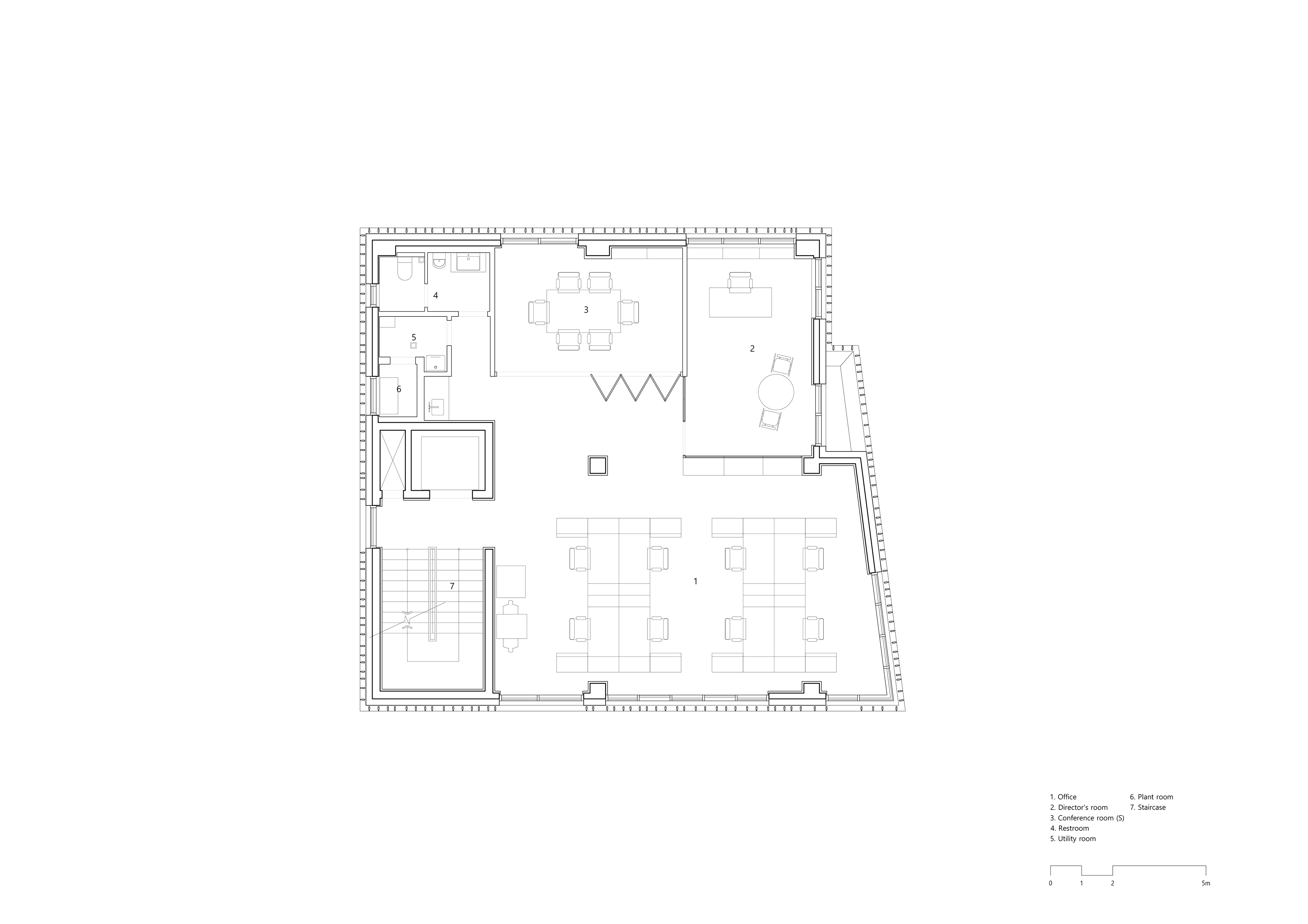

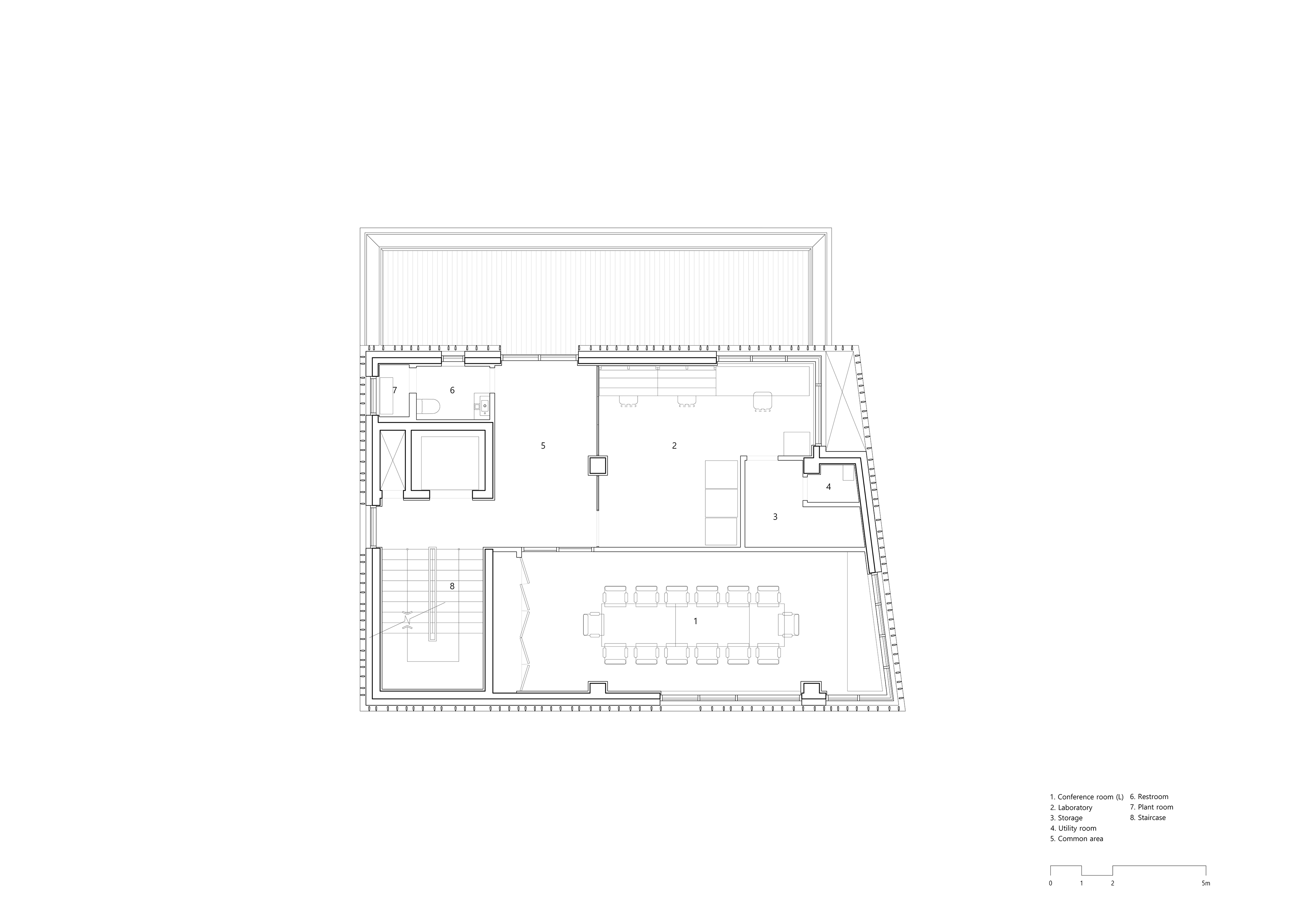

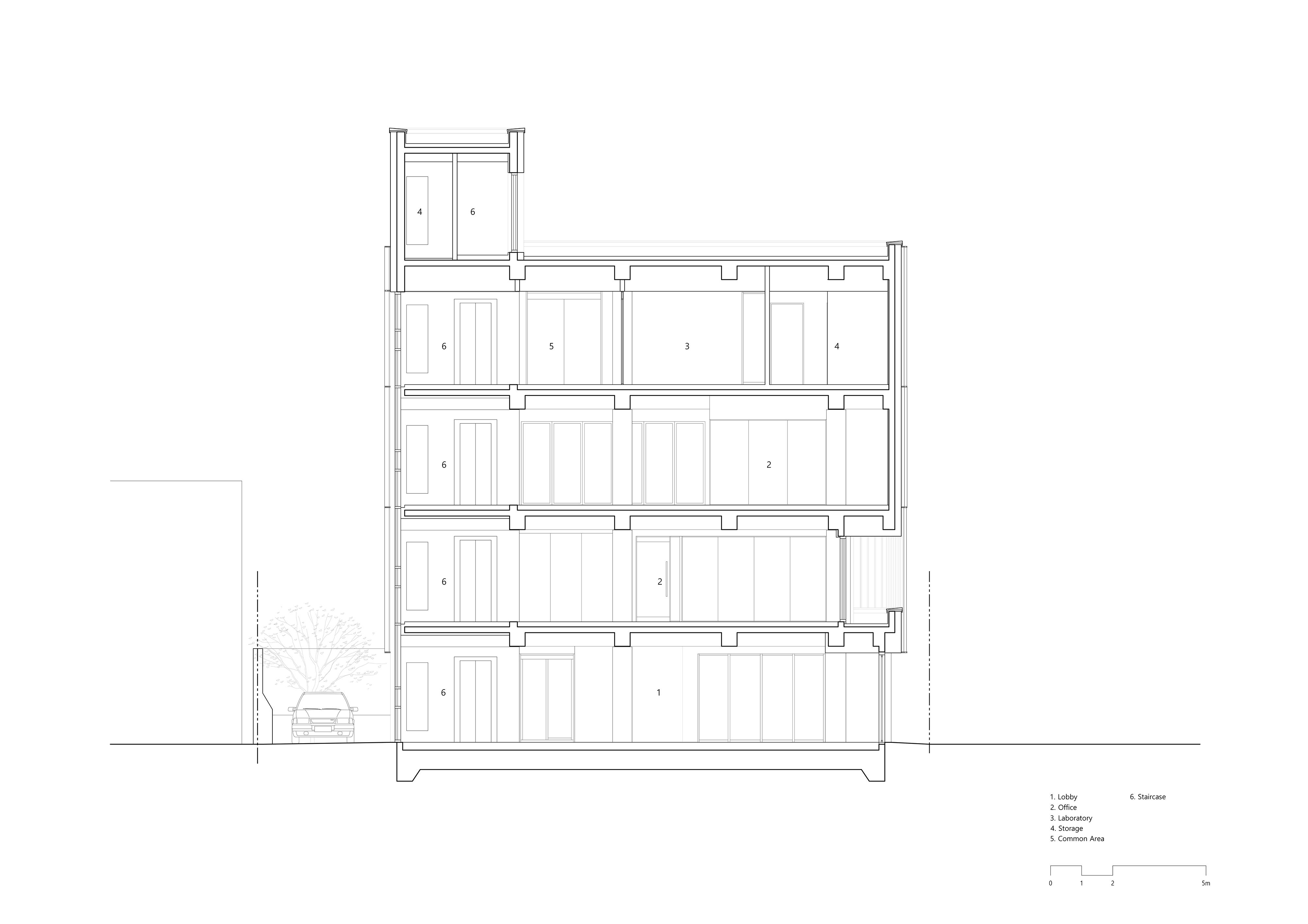

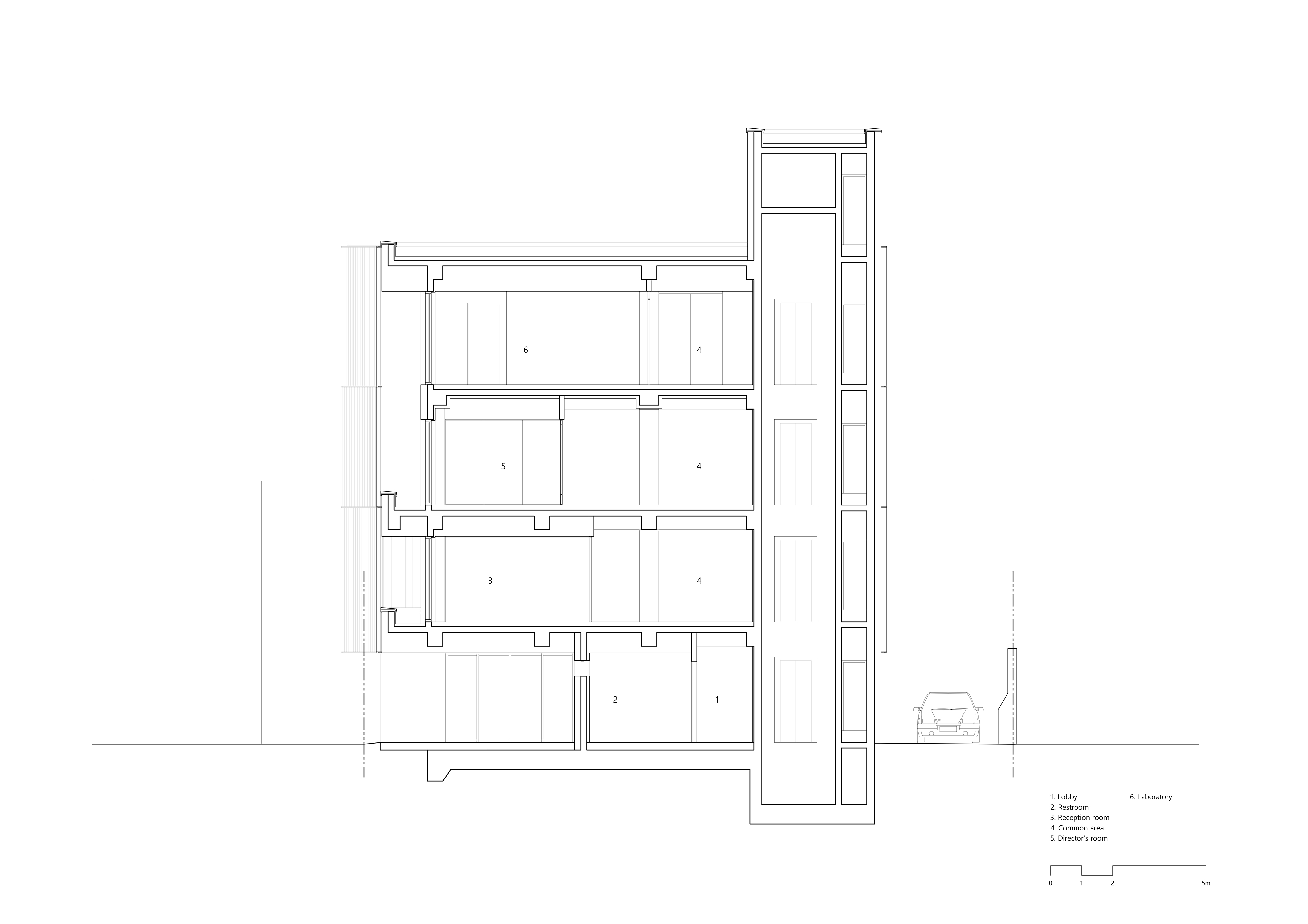

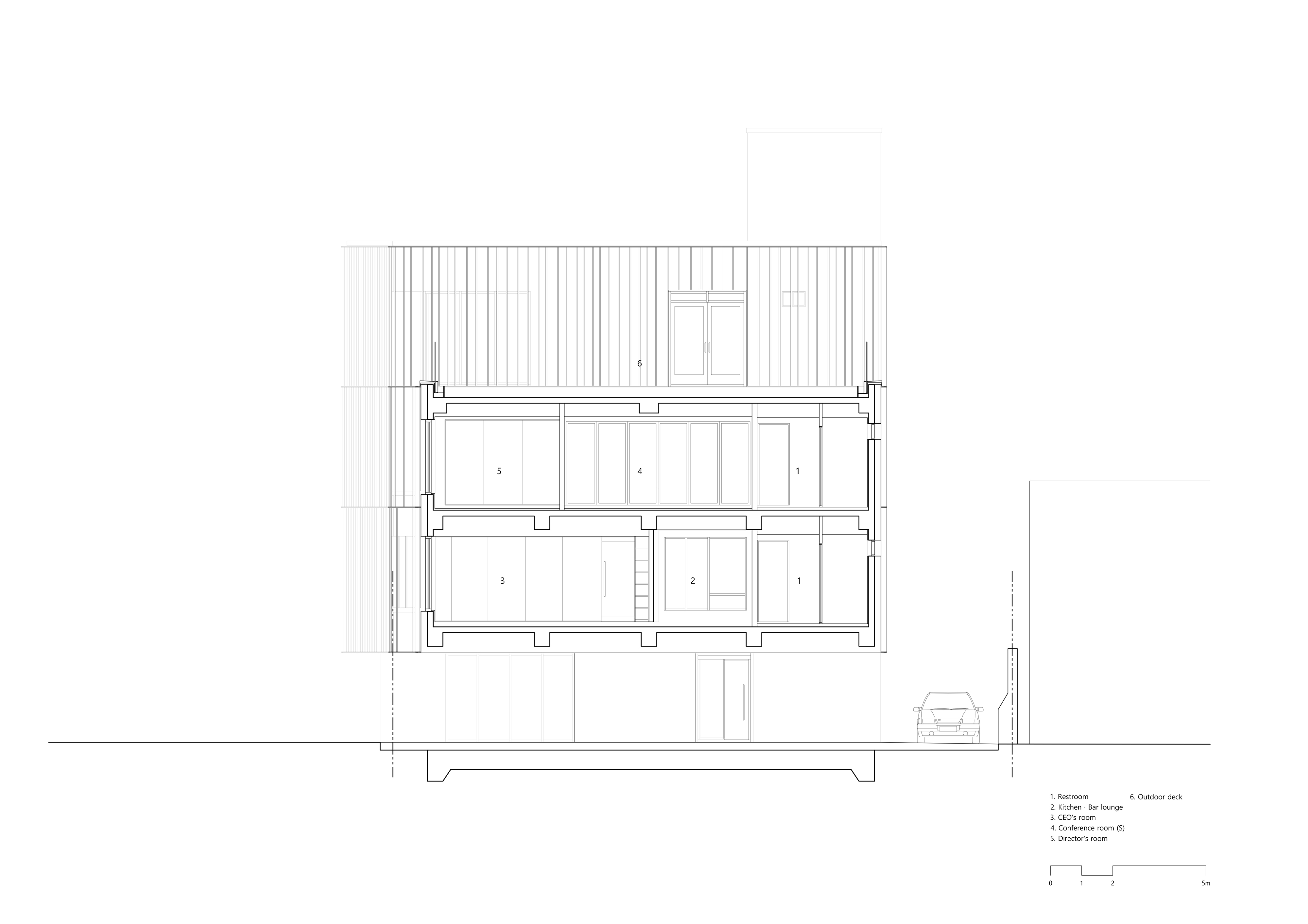

Program | Office + Chemistry Lab + Coworking Lounge

Completion | 2022

BCR | 59.34% (60% Required)

FAR | 194.5% (200% Required)

100% BIM Modeled Project

Scope of Design Servies | Architectural Design, Architectural Project Design Consulting, Interior Design, Furniture, Fitting & Equipment, Signage Consulting

Architect of Record | Doall Archtiects

Structural Engineer | Eden Structural Engineering Group

MEP Engineer | Ireh MEC

GC | Hoga Construction Co., Ltd

Electrical Subcontractor | Franklin Electrica Power Co., Ltd

How can beauty and science be integrated?

The Beauty of Science: A Blend of Scientific Precision and Architectural Elegance

The Beauty of Science serves as the new

headquarters for Company S, a global silicone distributor in Seogyo-dong,

Seoul, embodying SS2 Architects’ innovative approach to design. This project

not only meets functional requirements but also explores the philosophical

relationship between materials, environment, and users. The client’s unique

dual role as both salesperson and scientist influenced the building’s design,

creating a space that supports commercial activities alongside scientific

exploration.Recognizing the client’s material sensitivity, SS2 carefully considered how the building would respond to environmental factors such as sunlight, rainwater flow, and the effects of aging. The design anticipates how materials interact with sunlight, rainwater flow, and the effects of aging over time, resulting in a resilient, adaptable structure that balances durability with aesthetics.

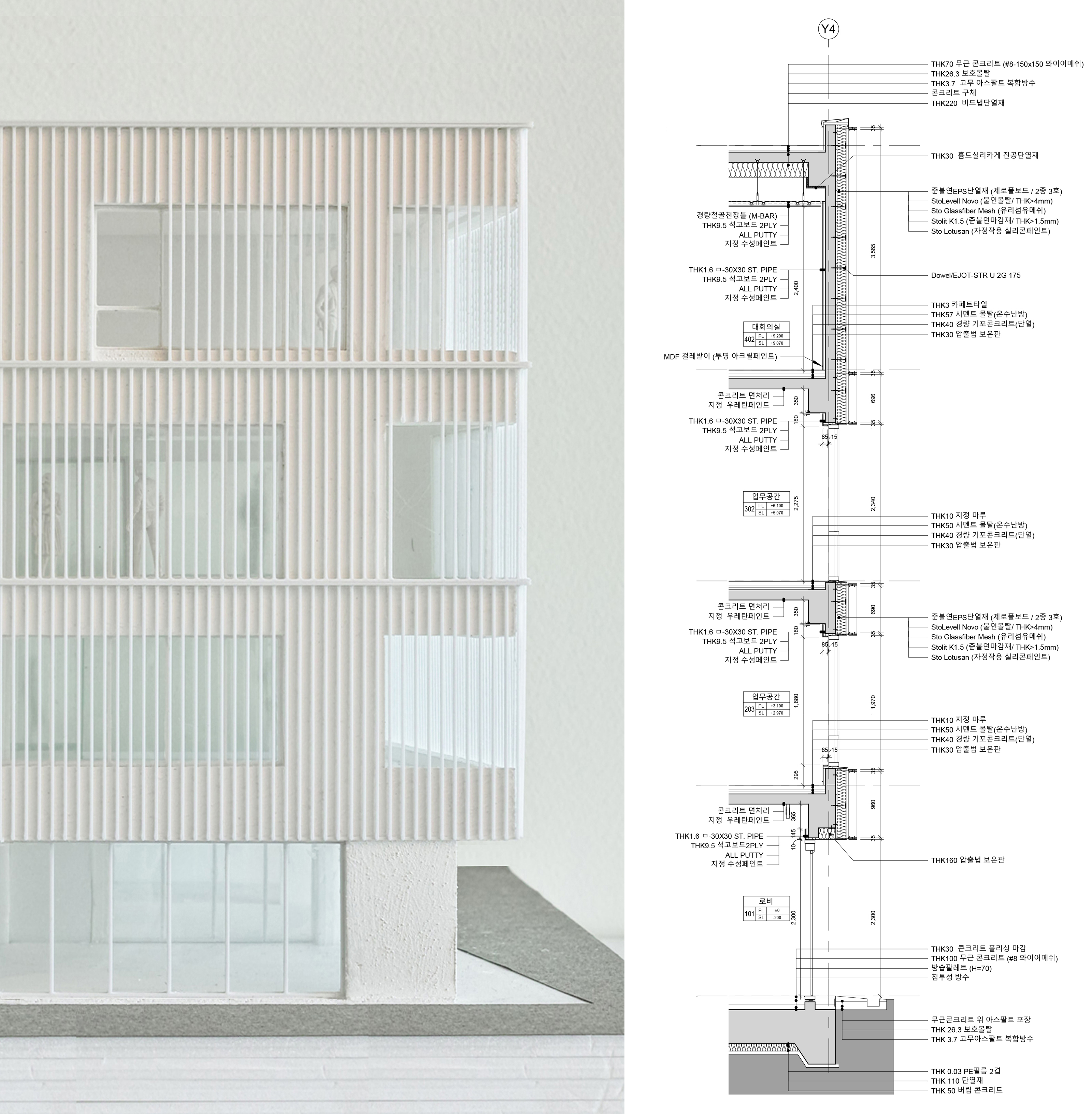

A defining feature is the customized aluminum louver system, which controls sunlight, provides privacy, and creates buffer zones—balconies and verandas—on each floor for natural ventilation and outdoor comfort.

To optimize performance, SS2 employed fumed silica insulation and anodized aluminum louvers on Sto Lotusan-coated surfaces for superior insulation and pollution resistance. BIM simulations enabled precise material quantification and efficient value engineering. Prefabricated, lightweight aluminum louver modules, developed through mock-up testing, were installed without caulking, allowing quick, seamless assembly. All internal walls, except the concrete core, are drywalls, accelerating construction and facilitating flexible future layout changes.

Situated near Hongdae Station, an area with a bustling commercial scene and high pedestrian and vehicle traffic, this building—primarily intended as office space—required a design that was neither overly open nor too closed off. Given that Hongdae is an area where the street scenery changes relatively quickly, we aimed to create a building that remains unaffected by its changing surroundings. The design aspires to maintain a refined appearance over time, offering a timeless quality that avoids monotony.

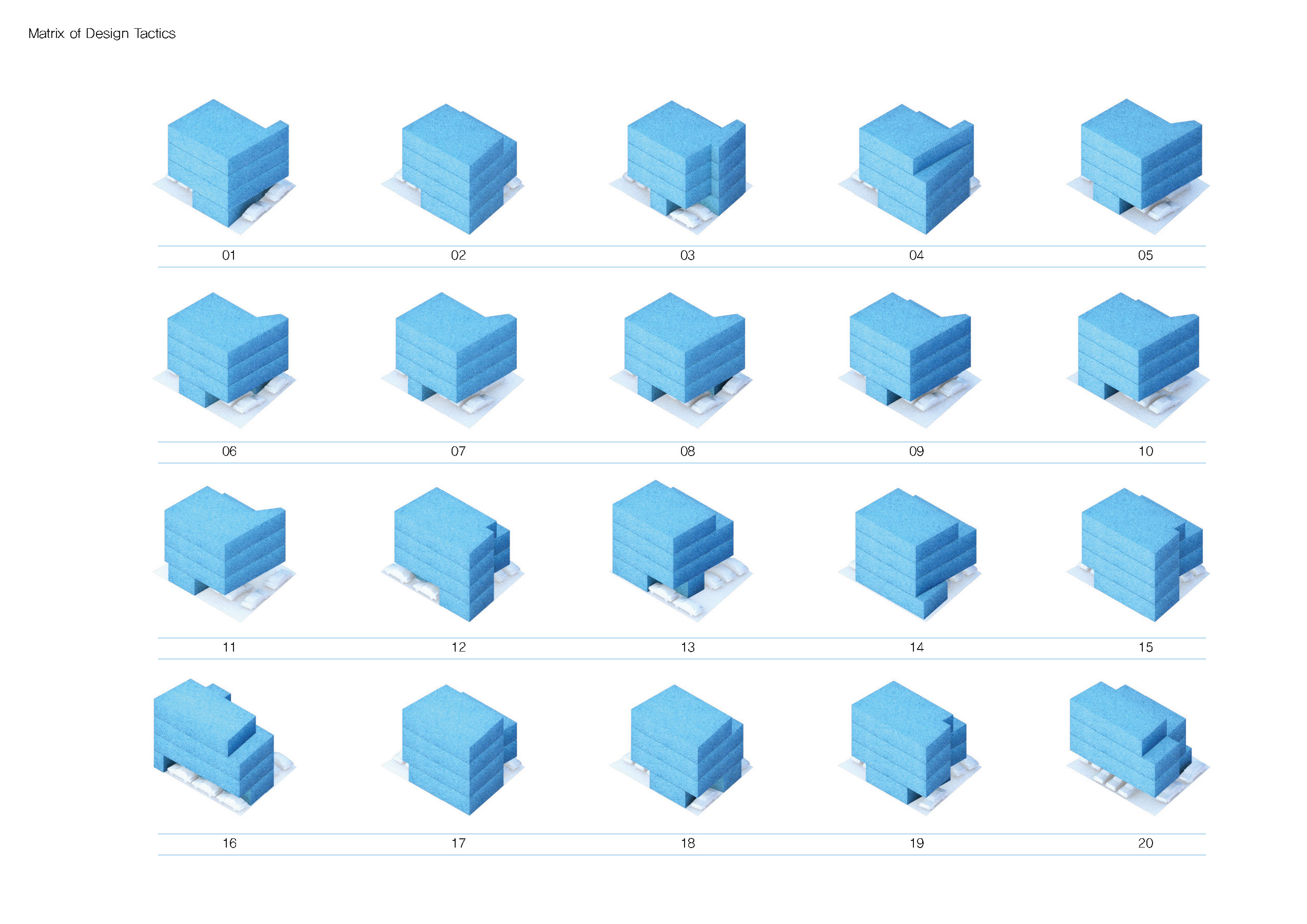

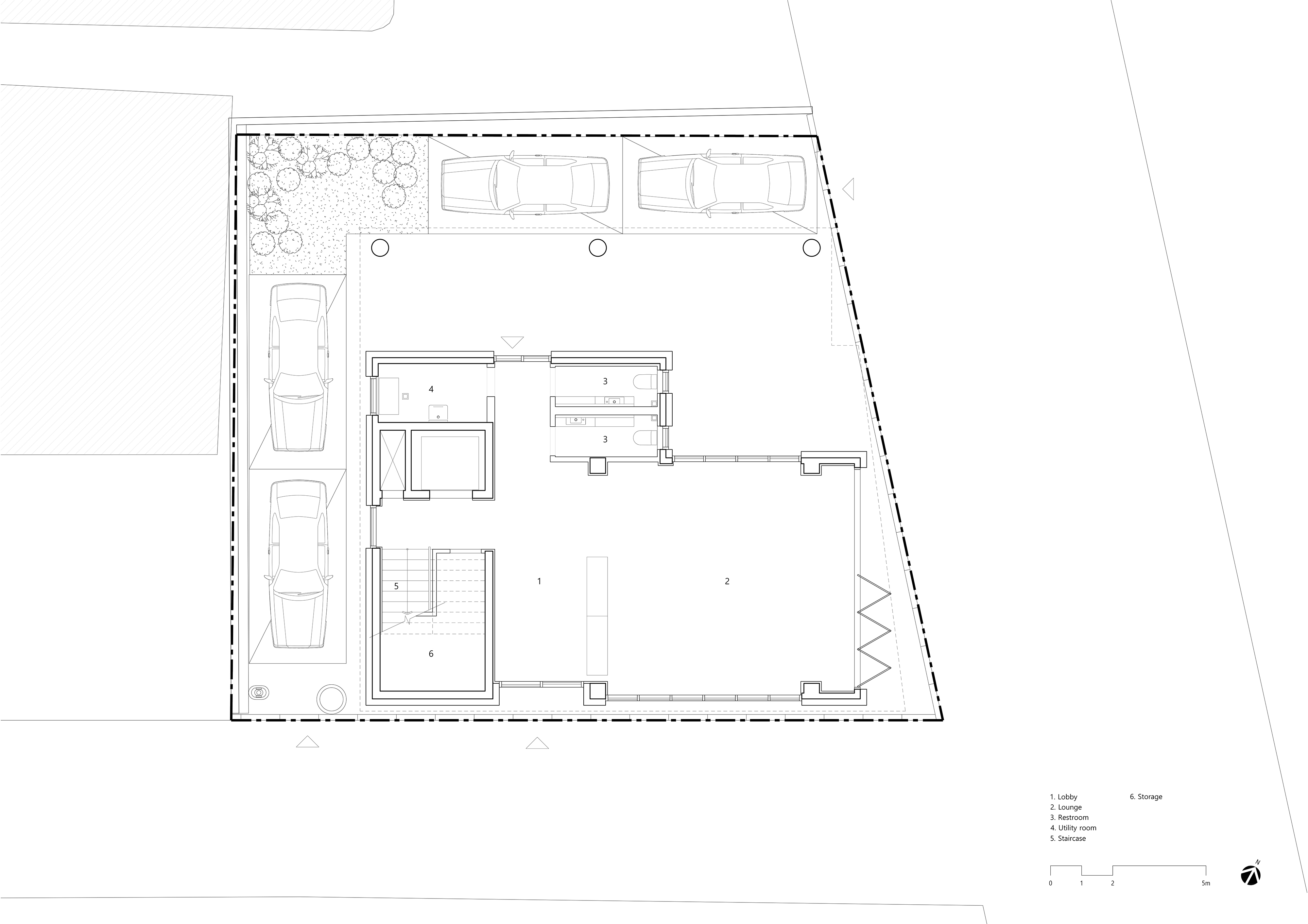

Smooth Vehicle Access: Key to Success in Sales and Promotion

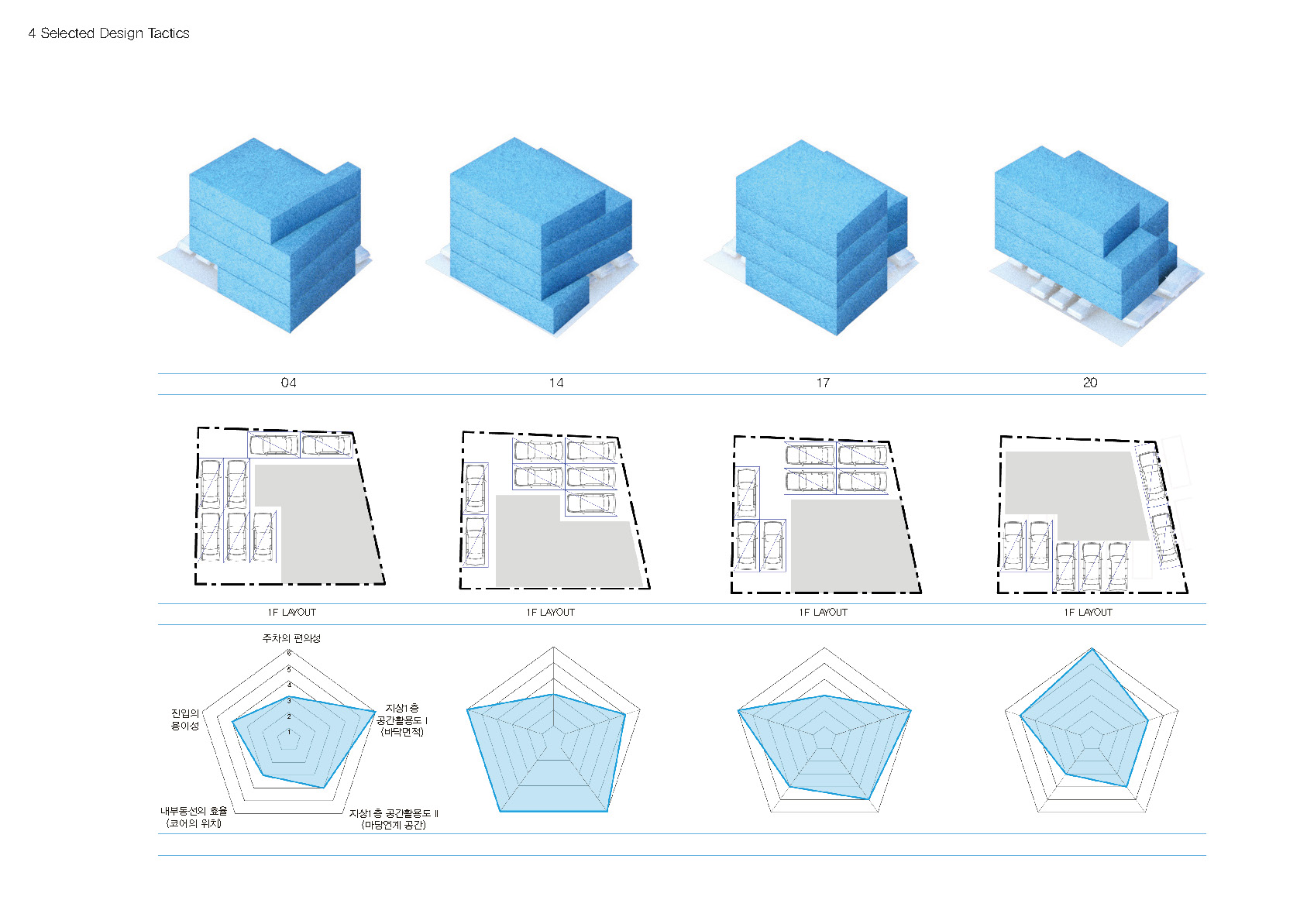

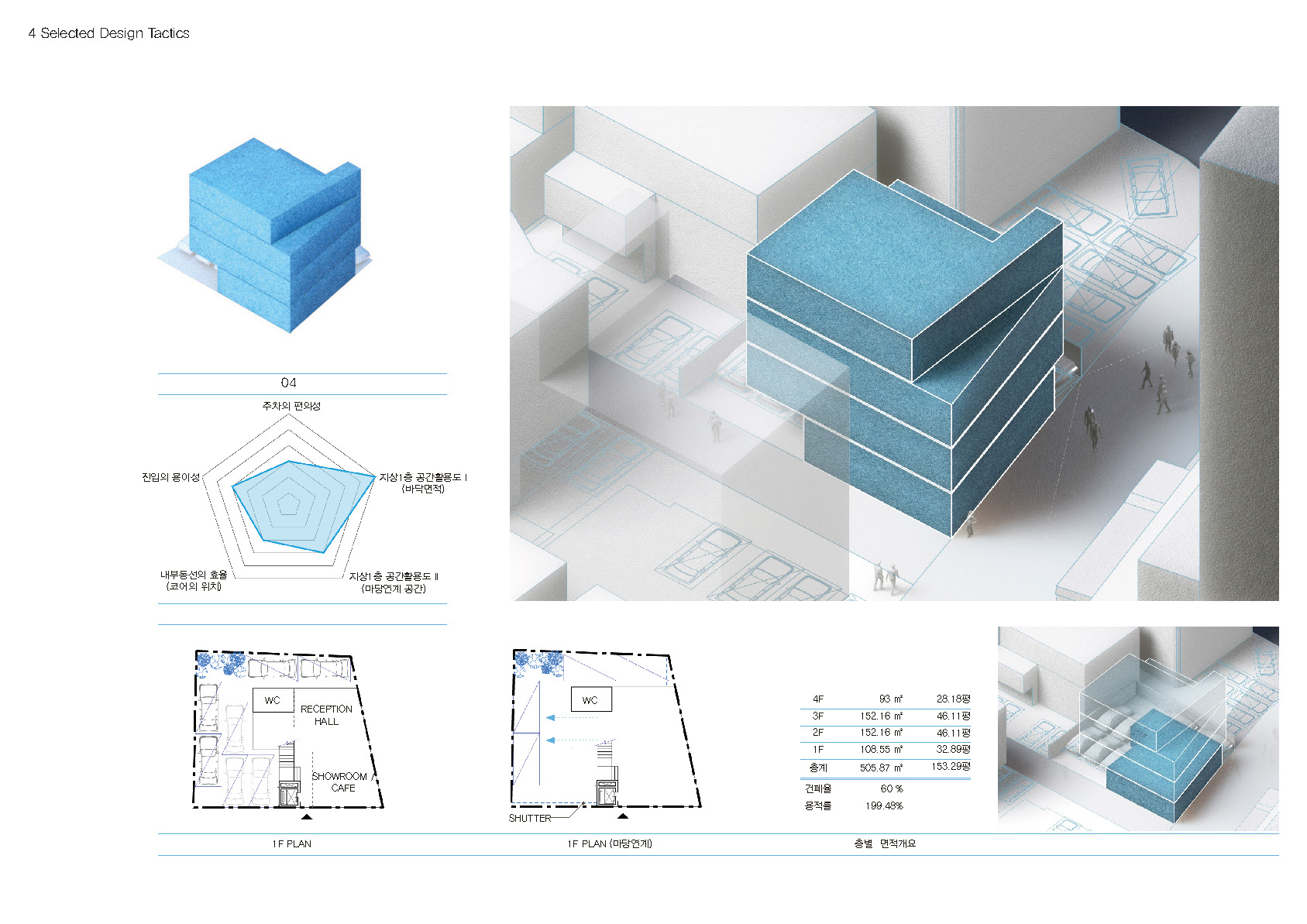

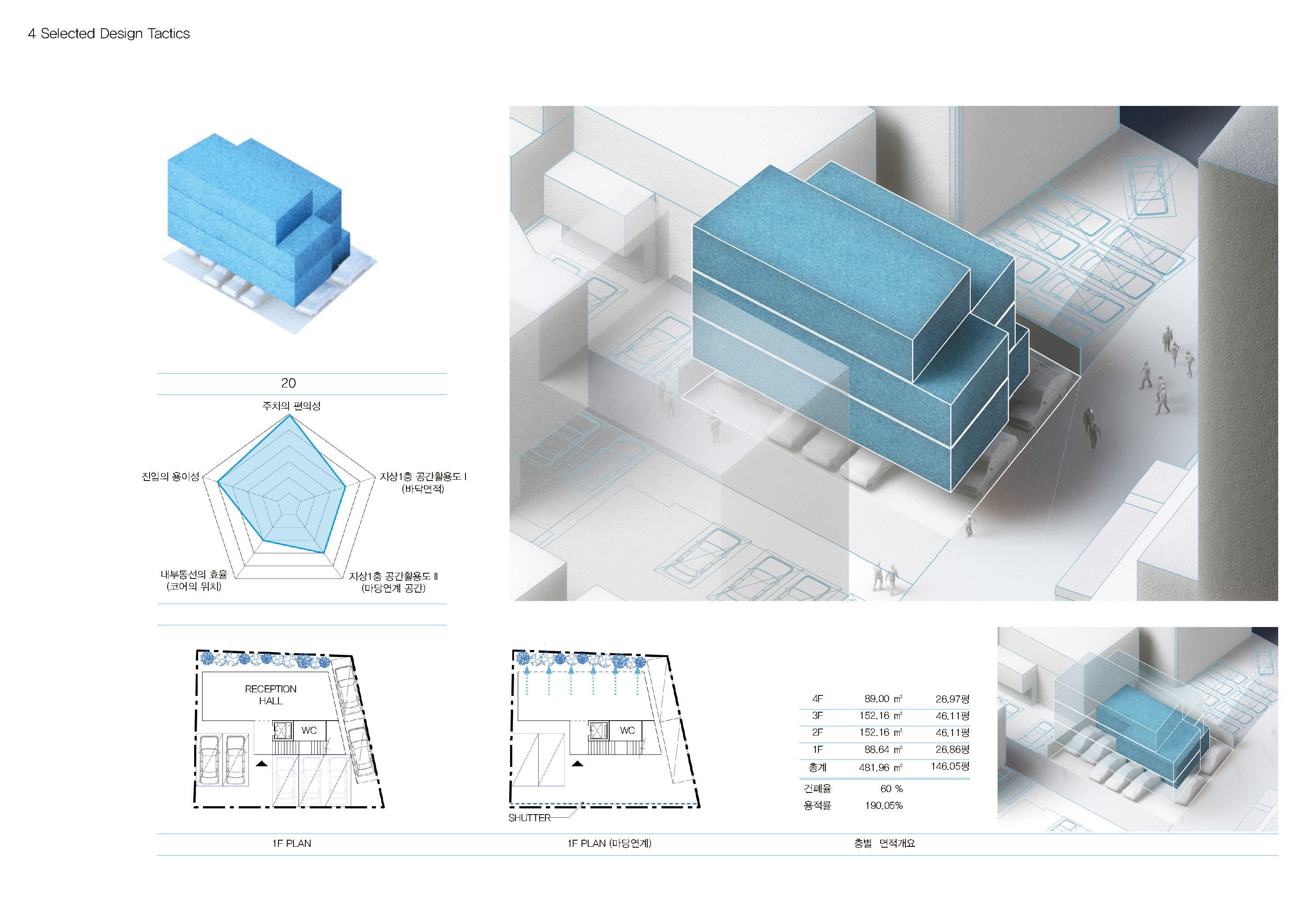

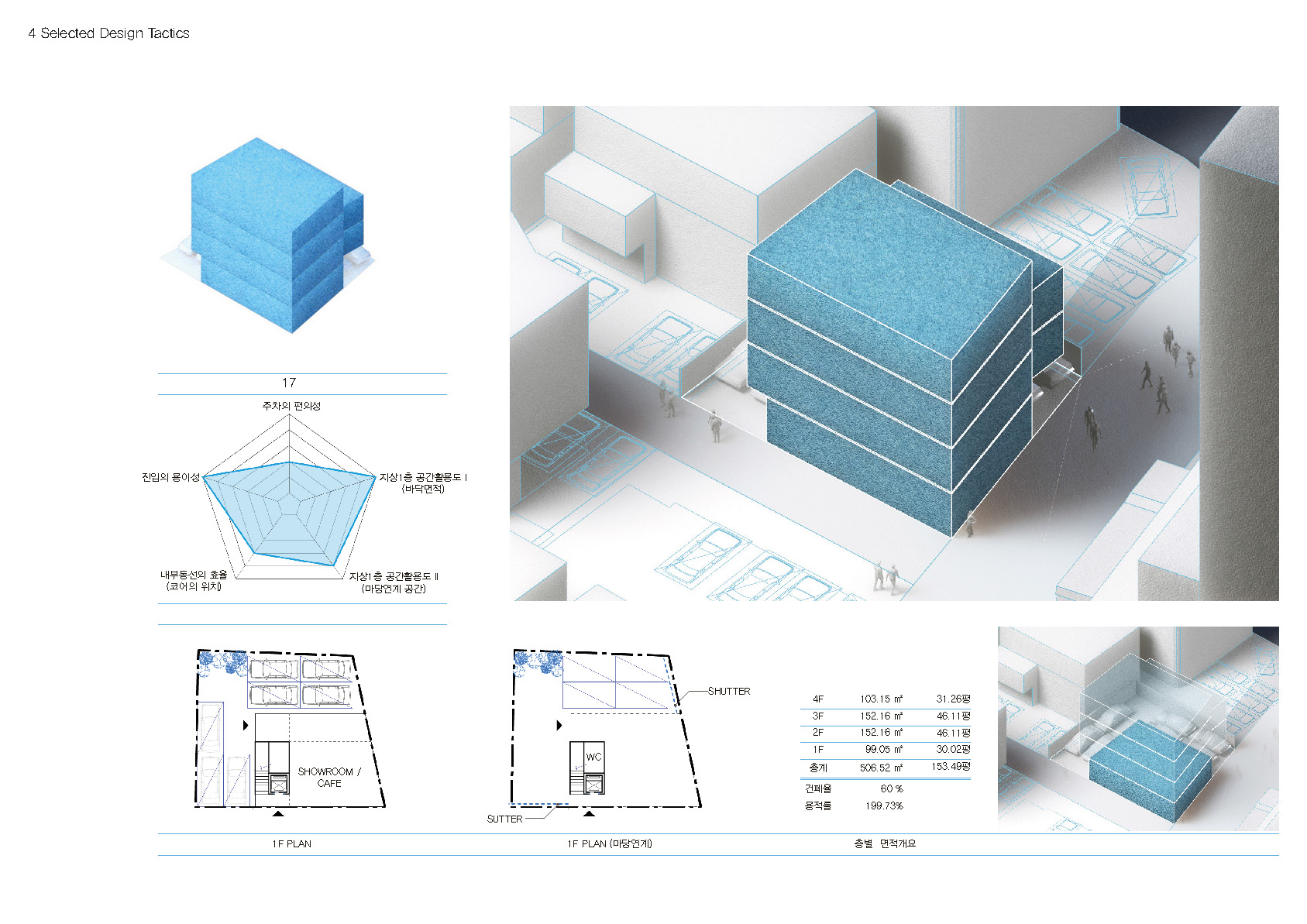

The client requested a plan that would provide ample parking for at least 8 vehicles for the sales department without any inconvenience.The design process was approached like a scientific experiment, with the client viewed as a "salesman-scientist." SS2 set the highest control variable as parking convenience and added secondary variables one by one, including the utilization of internal and external space on the first floor, the efficiency of internal circulation according to the location of the core, the ease of entering the workspace, and the arrangement of the program. The design options were analyzed using a radar chart.

The client requested a plan that would provide ample parking for at least 8 vehicles for the sales department without any inconvenience.The design process was approached like a scientific experiment, with the client viewed as a "salesman-scientist." SS2 set the highest control variable as parking convenience and added secondary variables one by one, including the utilization of internal and external space on the first floor, the efficiency of internal circulation according to the location of the core, the ease of entering the workspace, and the arrangement of the program. The design options were analyzed using a radar chart.

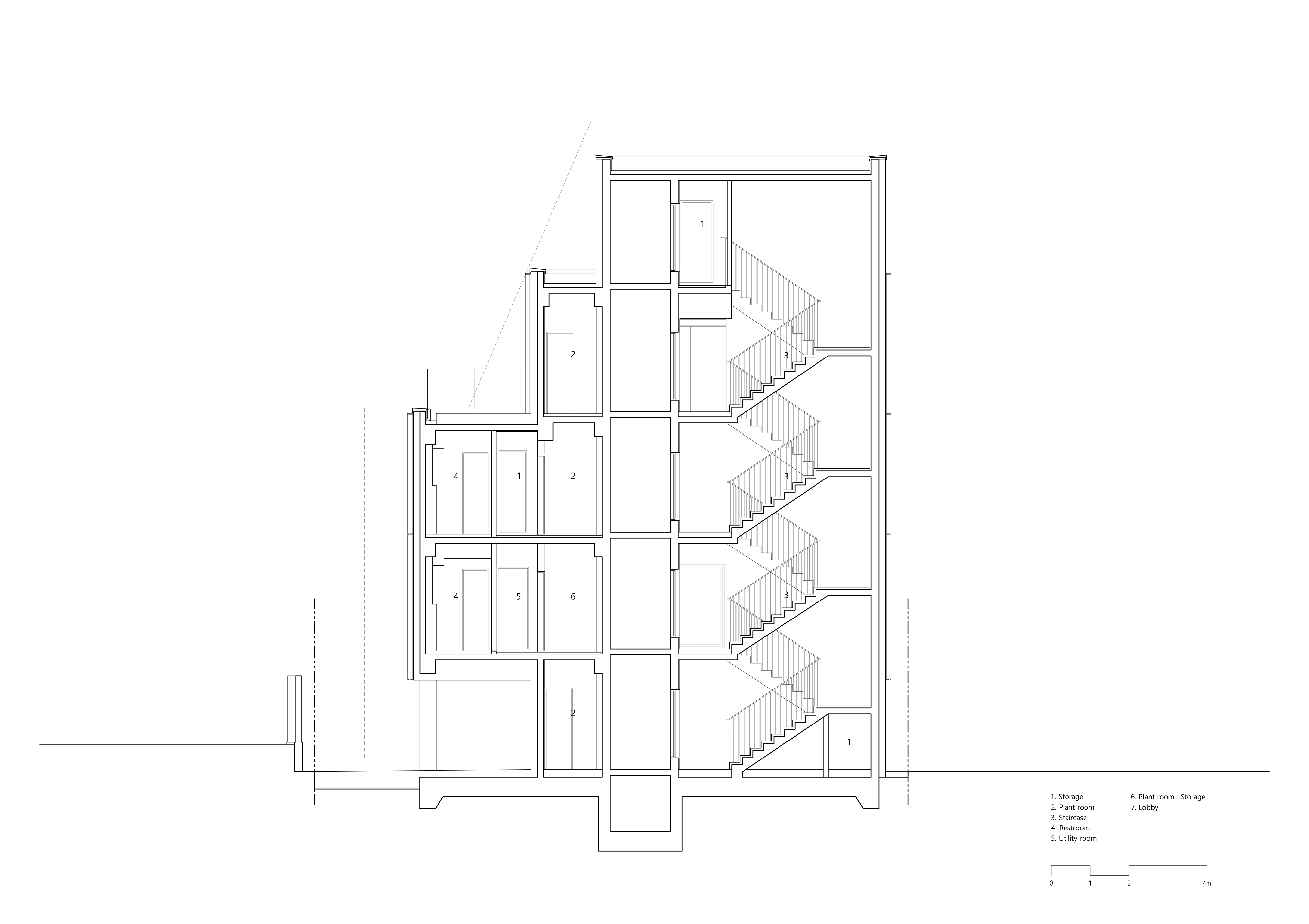

To combat height restrictions, SS2 placed numerous windows in buildings with low floor heights, bringing in the vista and creating a sense of openness. Aluminum louvers were also installed to control the amount of insolation and visually shield the building. Balconies and verandas on each floor, along with windows, were included to maximize natural ventilation. The laboratory was located on the top floor facing north, opening towards the street and controlling insolation. The ground floor is planned as a lobby but can be used as a parking space by opening it widely, providing a total of 9 parking spaces.

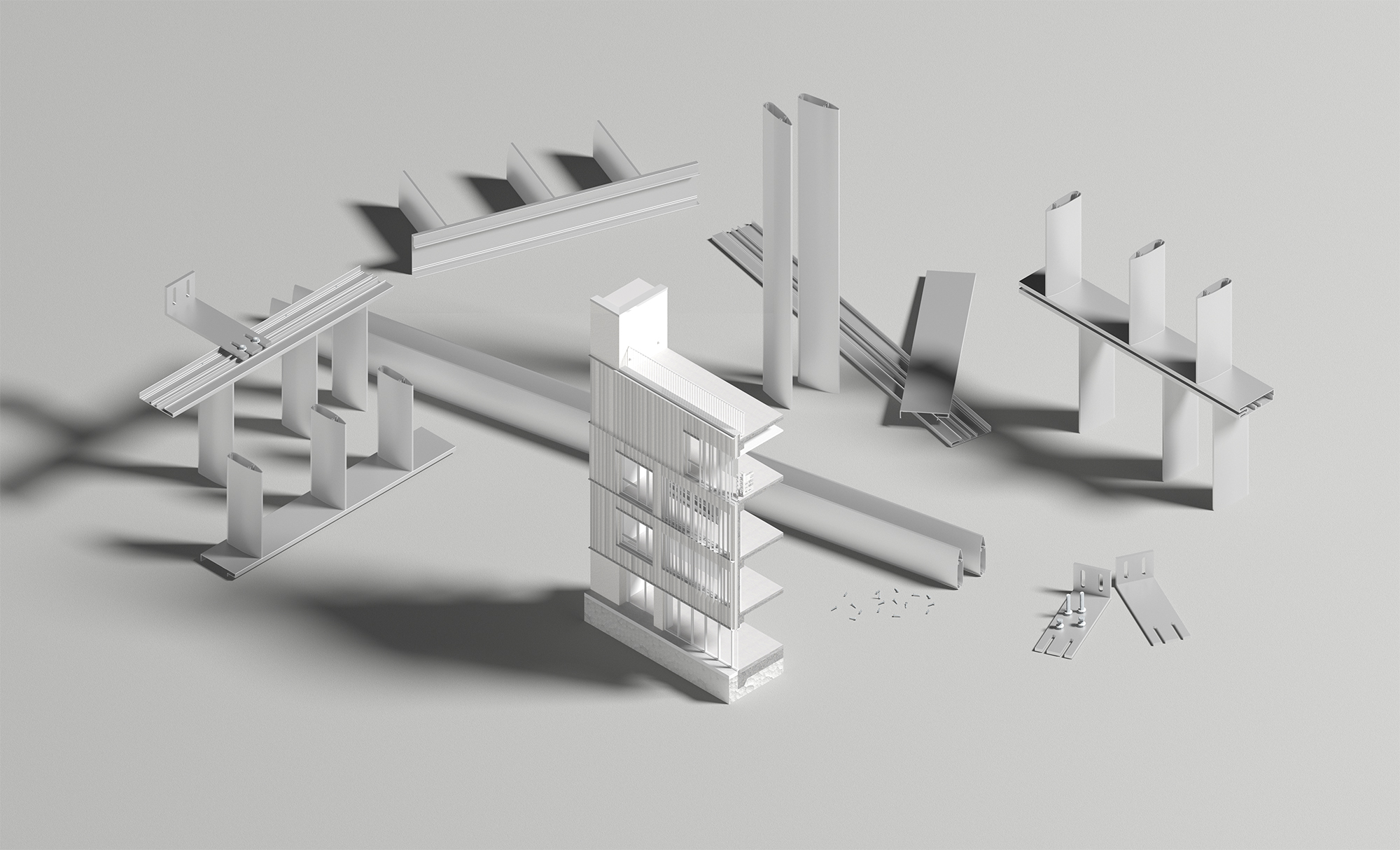

CUSTOMIZED LOUVER ASSEMBLY DETAIL

In SS2's fabrication lab, life-sized mock-up tests were performed with 3D printers and CNC machines, and the louver cross-section and bonding details were tested. In the field, the louvers were assembled as unit modules without caulking joint. All internal walls except for the concrete core are dry walls to accelerate construction and facilitate internal layout changes in the future.

In SS2's fabrication lab, life-sized mock-up tests were performed with 3D printers and CNC machines, and the louver cross-section and bonding details were tested. In the field, the louvers were assembled as unit modules without caulking joint. All internal walls except for the concrete core are dry walls to accelerate construction and facilitate internal layout changes in the future.

The building performance was enhanced by using high-performing materials and finishes while keeping the details simple. Fumed silica-based insulation and triple-glazed aluminum system windows improved insulation, while the anodized aluminum louvers on the Sto Lotusan paint coating enhanced pollution resistance. Sophisticated simulations were performed during design and construction administration through BIM design, allowing for accurate material quantification and data for VE. Lightweight, prefabricated aluminum louver modules were developed, which were easy to assemble, install, and maintain.